Our Facilities that can meet perfection

With our extensive range of equipment and machinery, we are well-equipped to handle various manufacturing processes and deliver high-quality fine blanked components to our customers. Our state-of-the-art machinery ensures efficiency, accuracy, and consistency throughout the production cycle.

Infrastructure

Our company boasts a sprawling area of 45,000 square meters, providing ample space for our manufacturing and administrative facilities. We have carefully designed our infrastructure to cater to diverse needs.

Office Building

Our dedicated office building spans across 250 square meters, providing a centralized space for efficient administrative operations and collaborative work.

Factory Building

With a spacious factory building covering an impressive area of 12,000 square meters, we have ample space to accommodate advanced machinery, assembly lines, and production processes. This enables us to meet the demands of our clients effectively and ensure smooth operations.

Training Center

We believe in the continuous development and upskilling of our workforce. That's why we have established a modern training center spread over 150 square meters. It serves as a dedicated space for training programs, workshops, and knowledge-sharing sessions to enhance the expertise and capabilities of our employees.

Refreshment Zone

We prioritize the well-being of our employees and understand the importance of creating a conducive work environment. Our nature resting facility covers an area of 300 square meters, providing a serene and rejuvenating space for relaxation and unwinding amidst nature.

Solar and Green Environment

We are committed to environmental sustainability. As part of our efforts, we have implemented solar energy systems to promote renewable energy. Additionally, we have incorporated green initiatives in our surroundings to create a harmonious and eco-friendly atmosphere.

Equipments and Machinery

At Fine Blanking Pvt Ltd, we take pride in our state-of-the-art equipment and machinery, which enable us to deliver high-quality fine blanked components. Here's an overview of our equipment and machineries:

Fine Blanking Presses

We have a range of precision fine blanking presses, including Feintool Swiss make presses with capacities ranging from 160 tons to 800 tons. These presses are equipped with cutting-edge technology, allowing us to manufacture components up to 12 mm thickness with utmost precision

Press Tonnage | Quantity |

|---|---|

Feintool Swiss Make 160 Ton Fine Blanking Press | 5 |

Feintool Swiss Make 200 Ton Fine Blanking Press | 1 |

Feintool Swiss Make 250 Ton Fine Blanking Press | 1 |

Feintool Swiss Make 400 Ton Fine Blanking Press | 2 |

Feintool Swiss Make 630 Ton Fine Blanking Press | 1 |

Feintool Swiss Make 800 Ton Fine Blanking Press | 1 |

Finishing Machines

To ensure the finest finishing of our components, we have a variety of finishing machines at our disposal. This includes belt grinders, vibro finishing machines, vertical disc grinders, and orbital hydraulic/pneumatic riveting machines. These machines play a crucial role in achieving the desired surface finish and overall quality of our products.

Finishing Machines | Quantity |

|---|---|

LVD Belgium Shearing machine of 16 x 4000 mm | 1 |

Niederberger Swiss make Belt Grinder | 1 |

Rosseler German make Vibro finishing Machines | 1 |

Blanchard US make Vertical Disc Grinders | 2 |

Fellows Make – Gear Shaping Machine | 1 |

Vibro Finishing Machine | 5 |

Belt Grinders | 3 |

AURAM make Tapping Machines | 2 |

ACE make CNC Turning Centres | 2 |

Gang Drilling m/c, Tapping m/c, Orbital Riveting m/c, etc. | - |

Centrifugal Vibro Finishing Machine | 1 |

Tool Room

Our tool room is equipped with the latest machinery, including CNC machining centers, EDM machines, and surface grinding machines. These advanced tools enable us to design, develop, and manufacture fine blanking tools with exceptional accuracy and efficiency.

Tool Room |

|---|

SIP Swiss make Jig boring M/c |

Electronica EDM Sinking M/c |

Blohm Surface Grinder |

Conventional HMT Milling, Cylindrical Grinding, Surface Grinding |

Mitsubishi Japan make Wire Cutting Machine |

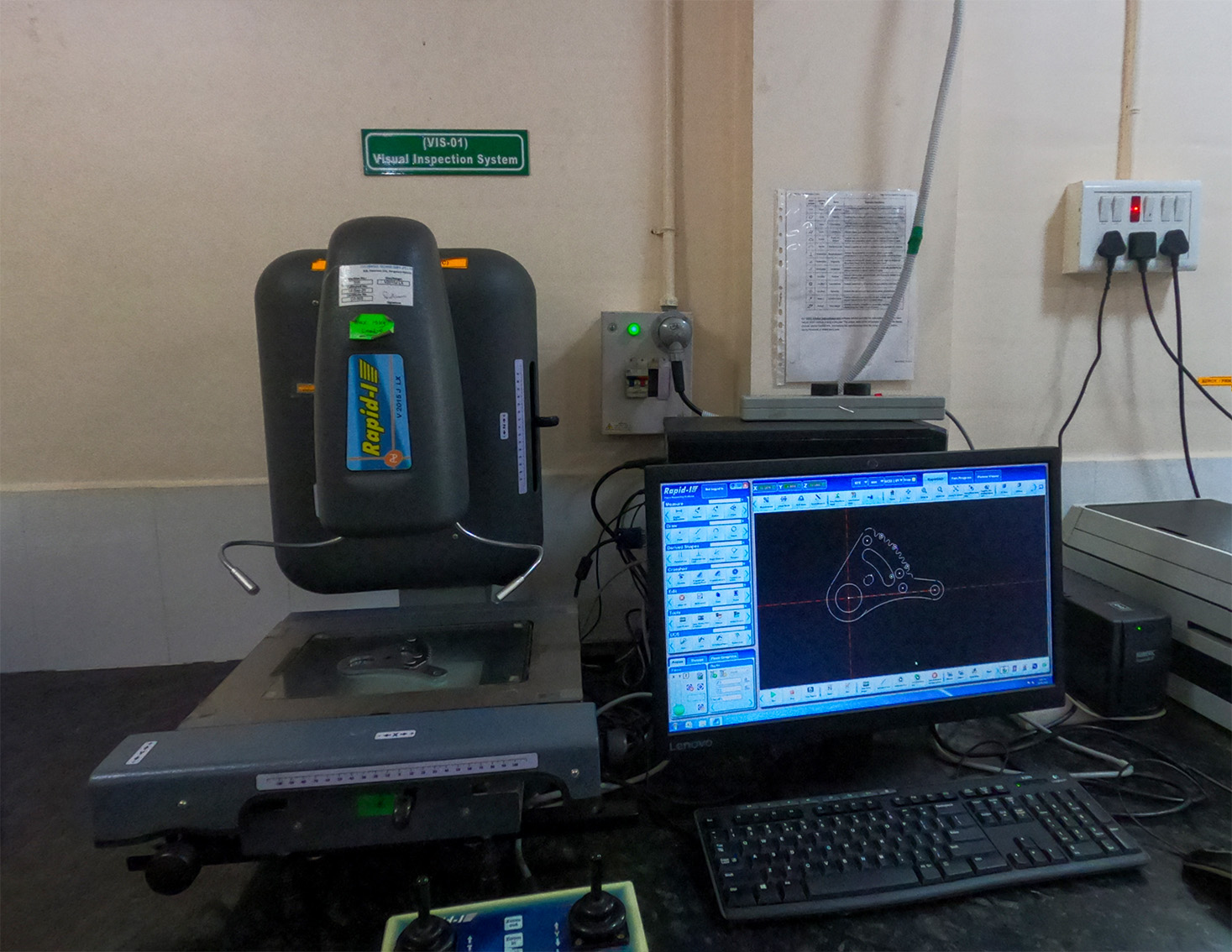

Inspection Equipments

At Fine Blanking Pvt Ltd, we utilize a range of advanced inspection equipment to ensure the highest quality standards for our fine blanked components.

Inspection Equipments |

|---|

Mitutoyo Japan make CMM Measuring M/c |

TESA Profile Projector |

Mitutoyo Surface Tester |

Mitutoyo Inspection Equipments |

Keyence Image Dimension Measuring System |

Rapid Vision Measuring system |

Tool Development

We have so far produced 410 + Fine Blanking Tools in house for different organizations up to 12 mm thick material.

Human Resources

We have Skilled Workers & Engineers available from:

- Swiss Sponsored Tool & Die Mfg. NTTF Training Center at Dharwad (20 km. From Hubli).

- Govt. Tool Room Training Center (GTTC) at Hubli, Belgaum, Dandeli & Bagalkot within 100 Km. (Indo – Danish Project).

- Engineers – Degree & Diploma colleges 16 People and ITI Training Centres 10 People in a radius of 100 Km.

Raw Materials

To guarantee the highest quality in our fine-blanked components, we carefully select raw materials from trusted suppliers.

- Stainless Steel: We source stainless steel materials, including SS 304, SS 409, and SS 430, from Jindal Stainless in Hisar and Jajpur.

- High Tensile Strength Steels: Our high tensile strength steels, such as ST37, IS-2062, and ST52-3, are procured from Jindal Vijaynagar Steels in Bellary.

- High Strength Low Alloy Steel: Materials like S420MC, S550MC, 16MNCR5, and SCM435 are sourced from reputable suppliers such as Tata Steel Processing in Bangalore.

- Low Carbon Steels: We rely on suppliers like Tube Investments of India in Chennai for low carbon steels like IS 513 D, DD, EDD, SAE-1010, and SAE-1020.

- Medium Carbon Steels: Our medium carbon steels, including C-45 and C-60, are sourced from Pennar Industries Ltd in Hyderabad.

- Copper: We utilize ETP Grade Half Hard and Full Hard copper from VNS Industries in Mumbai.

- Tool Steel: For our tool steel requirements, we trust suppliers like Buderus & Bilstein (Germany) and Poongsan Corporation (Korea), as well as Bohler Uddeholm Pvt Ltd in Chennai.