Precision in Metal Forming

Fine blanking technology enables the creation of intricate and complex shapes with remarkable accuracy. From automotive to aerospace, our fine blanked components find applications in diverse industries where precision is paramount.

What is fine blanking?

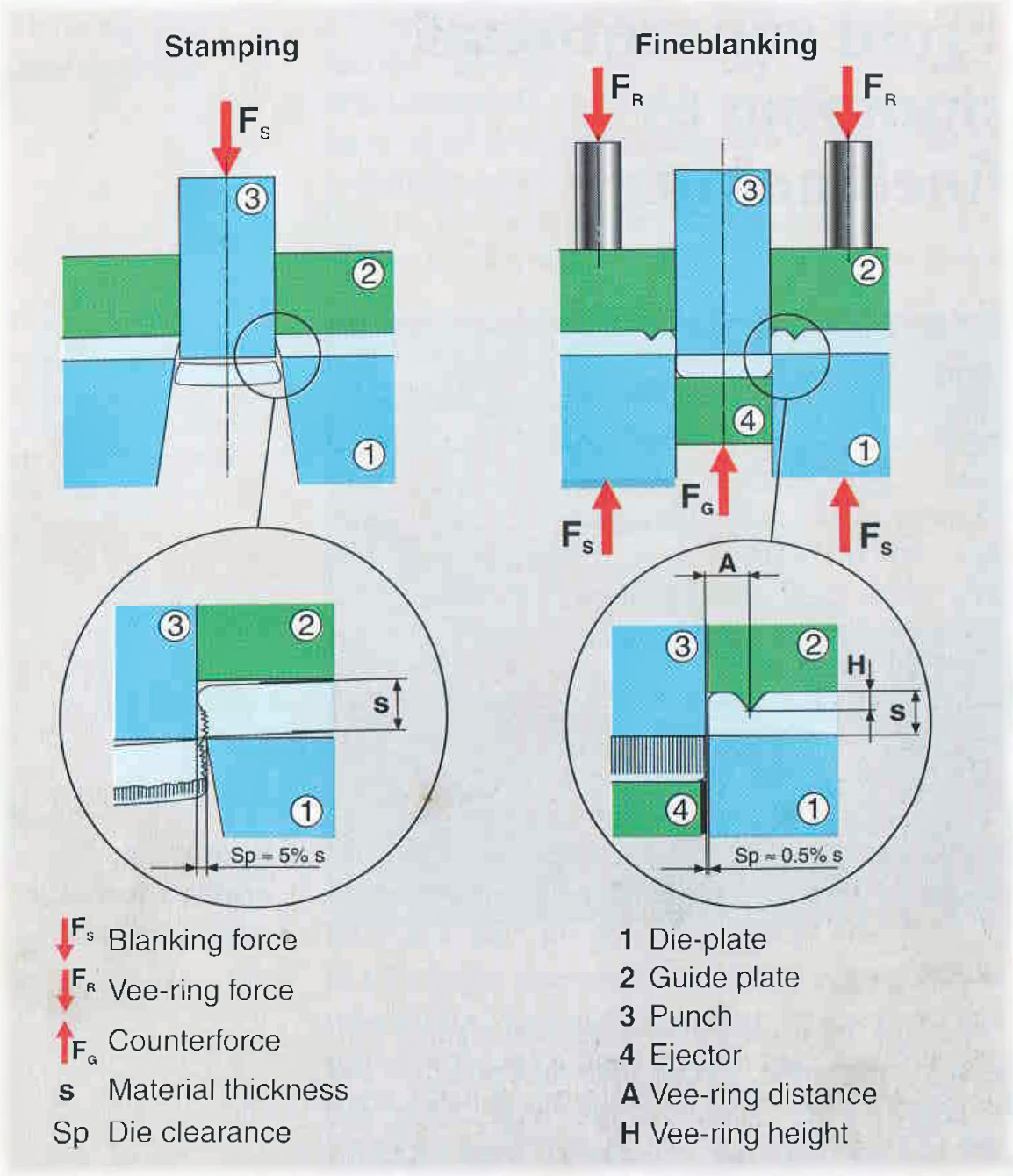

Fine blanking is a specialized stamping process that produces parts of exceptional accuracy, flatness, and edge characteristics when compared to conventional stamping. It is also known as precision blanking. Fine blanking involves specific parameters that set it apart from general blanking, which is a single-stroke shearing of closed contour profiles. The parts produced through fine blanking exhibit unique quality characteristics such as a full sheared edge and flatness. The process requires the manufactured product to have a full contact surface on the edge of the part, and it is based on the hydrostatic pressure effect, where the plastic forming force increases when pressure is applied to metal.

During the fineblanking cycle, not one, but three forces act upon the material. They are transposed through the guide plate, the ejector, and the pair of active elements - punch and die plate. These forces are:

- The vee-ring force

- The counterforce

- The blanking force

The main difference between conventional shear-cutting or "stamping"(left) and fine blanking(right)

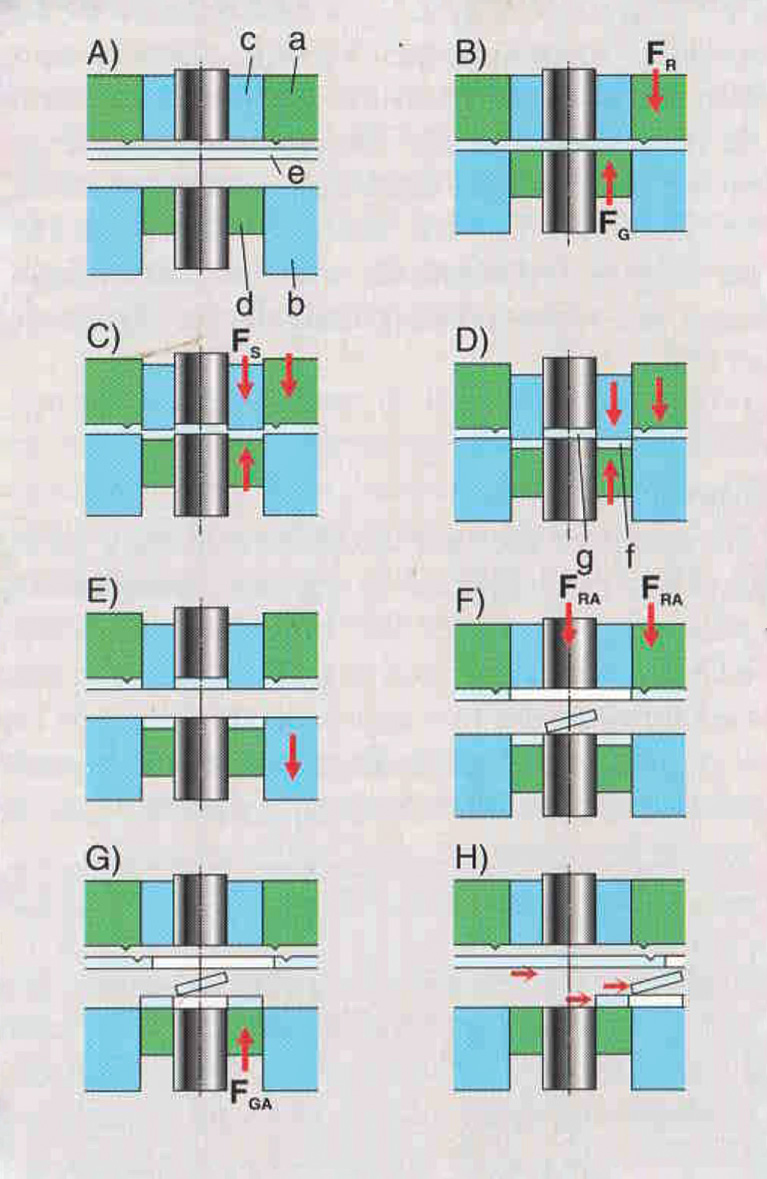

The complete fine blanking cycle: (a) Guide plate, (b) Die plate, (c) Punch, (d) Ejector, (e) Work material, (f) Fine blanked part, (g) Inner form scarp(slugs)

The fine-blanking cycle: The eight drawings in the figure show the complete fine-blanking cycle, with the production of a washer as an example. In (A) the tool is open, and the strip is pushed into position. The ram closes the tool at a fast approach speed, then slows to allow the inside of the tool to be automatically checked for the presence of any foreign body such as scrap from the previous cycle. If the tool is clear, the main piston is actuated (B). Under the effect (C) of the blanking force, the ram begins its cutting movement, during which the part is cut out and pushed into the die plate by a distance equal to its thickness. The scrap corresponding to the central hole is pushed by the counter-force inside the punch.

All three forces act simultaneously. At the end of the cycle (D), the hydraulic pressures are removed and the tool opens again (E).

Cut edge of parts produced by stamping (above) and fine blanking (below)

Cut edge:

The most obvious feature of fine blanking is the completely smooth edge obtained on the part, which, if required, can be free of cracks and tearing over the entire thickness of the material. Fineblanked edges can fulfill mechanical functions without needing any secondary machining. Stamped parts, on the other hand, have edges which are partly cut, partly torn, and in many cases rough and tapred. Unlike fineblanked parts, stamped parts must be further machined by a chip removal process before the edges can perform mechanical functions.

Besides having smoother edges, fineblanked components are also flatter than stamped parts. Close tolerances on dimensions and quality can be held easily in fineblanking.